Interior toggle lamp/switches - repair procedure

| Last modified 2005 APR 07 04:37:58 GMT |

To: xj-s@jag-lovers.org

One of the (several) problems with the lighting in my XJSC when I acquired

it were the two rear courtesy lamps. I popped them out and found that the

switch assemblies (the lens itself is the switch), were broken at one of the

pivots: the little metal-clad plastic nub was sheared off. Both switches

suffered this same problem.

I contacted Jaguar Heaven and found that they wanted $30 apiece for salvaged

switches. While I've got some other stuff I expect to be ordering from them,

I didn't feel that it was worth ordering a couple of used lamps if I could

fix the two I have (and reinforce them in the process). Here's the procedure

I used:

First, remove the lamp assembly. This is easily accomplished - the wiring

harness uses a form of bullet plugs, and all you have to do is unplug them.

Note that there are two conductors on one side (the switch side), and a

grounding wire on the other. One of the hot conductors is wired to the

door/courtesy lamp circuit, and the other is 12V constant. You probably want

to make note of what wire goes where, but it should be easy enough to figure

out when you have the switch fixed anyway.

[Noted on both sides in my car: Purple/pink: ground. Black = constant 12V+,

purple, courtesy 12V+]

Examine the switch assembly - if yours failed the way mine did (and which it

appears to be the one real weak spot), then the side where the two hot wires

plugged into the assembly is the one that is loose.

[Note: D.U.M.B. design -- the side with the torque and spring pressure is the

one where the pivot is the plastic nub -- the OTHER side is a fully metal

sleeved peg, which they could have done on both sides, or AT LEAST, have used

the sleeved peg on the torqued side. Grumble.]

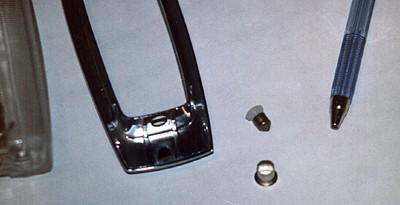

Things to look for are the small metal bearing and pressure spring (on the

hot lead side) - these provide the "click" and switch detent. Chances are,

the bearing is missing, and the spring may be as well (though in my case, I

am happy to report that the springs had remained in the assembly for both

lamps). If not, retrieve them and don't loose them. An envelope or

zip-lock baggie is a good place to put these small parts, though I have a

collection of clear plastic parts bins (6.5"W x 12.5"L x 3.5"H) which I use.

A quick look around the mounting location of the lamp, or brushing it with a

telescoping magnet (I've a neat mini-flexi lamp with magnet tip that works

well for this) might turn up the bearing or spring if they're missing.

Take a pair of needle nose pliers (my needle nose Leatherman(tm) tool worked

wonders here) and gently pull the lower spring (spring metal - not a coil

spring like in the switch itself) on the grounded side of the assembly

towards the middle of the lamp, while pressing down on the top of the spring

(so you don't torque it too much on the plastic lens). This is so that you

can get to the metal sleeved pivot pin that is in the housing on that side.

Pull out the pin and set it to the side in your parts bin.

Now you should have the metal sleeve exposed (specifically, there's enough

room to get at it from the side -- no pin occupying the middle). Take the

tip of your needlenose and carefully pull out the flaring (a slight bend

inward), stopping to rotate the sleeve every 2 or 3 crimps so that you keep

the part you're aligning on the open side of the ring (versus the side right

behind the faceplate, which interferes with the pliers' straightening motion).

When you've got the flare crimped out, you should be able to push the sleeve

back through the pivot hole towards the lens, where it will pop through (or

at least far enough back to clear the pivot hole to permit the lens to come

free of the frame). Remove the lens from the frame.

I did a bang up job on my first sleeve, so I took a metal-tipped disposable

pen and removed the ink and tip from it, and used the metal tip of the pen

and the pliers to carefully form it back into a proper circle, until I could

insert and remove the sleeve in the lamp housing pivot hole to my

satisfaction (I also did some light deburring with a sanding disc on a

Dremmel). A carpenters nail countersink tool could accomplish a similar

reforming job on the sleeve.

You're basically halfway there.

Now, you need to take the broken plastic pivot pin (from the other side of

the assembly) and the lens and carefully drill a hole into them (this is for

reinforcing them against a repeat of the shearing - if you simply epoxied or

superglued them back, they'd eventually break again). In preparation for

this, I got a couple of fine finishing nails (1/16" diameter), and using a

Dremel(tm) tool with a grinder bit attached, ground off the sharp points

until they were both basically flat. I switched bits to a sanding disc, and

sanded the burrs from the tip (not rounded, just nothing to catch on the

plastic).

First, with a felt-tip marker, mark the centre of the pivot pin and the

shearpoint on the side of the lens. If you'd like, you can use a pushpin to

make a slight divot at that marked spot (start with the broken off tip first

- don't divot the lens just yet). The slight divot is helpful in providing a

natural resting spot for the tip of the drill when you start drilling.

Insert a 1/16" drill bit into the Dremel (or equivalent drill tool), and

drill into the broken-off tip first (reason: it is MUCH easier to make a

positional error here because the part is so small, and as such, you can then

turn around and offset the hole you'll drill into the lens housing, where you

have more control, to compensate). Hold the tip firmly in a pair of pliers

or in a vice (but be careful not to apply so much pressure as to cause it to

deform or collapse). Drill down about 3/32 to 1/8" (there isn't much plastic

here to work with to start). Take the deburred tip of the finishing nail and

insert it into this hole and see how snug it is. Now, switch to the lens

housing and drill into it (repositioning the mark and using a pushpin to

divot as necessary - if you're off centre, note that the tip probably didn't

shear precisely flush to the lens -- remove the peg and mount it as if you

were fixing china and trying to line it up right). Note that from the side,

you can see how far your hole has gone into the plastic -- I'd suggest you

stop drilling about the point where you've got about 1/16" inch left of lens

before you've drilled all the way through (to get a more snug peg fit, and to

keep the metal pin from even possibly making contact with the hot lead

assembly - a no-no if you've drilled the tip to the point of making contact

with the metal -- you could conceivably ground out the hot leads to the body

when the lamp is switched on), though drilling all the way through shouldn't

hurt.

Clip the finishing nail to approximate length, and try a test fitting to see

how well aligned the pivot is. With the sanding or grinding wheel reattached

to the Dremel, finish the peg to length and deburr it.

After a test fitting, prep the surface sheared area of both the lens and the

pivot, plus a bit extra in the hole with superglue (if it isn't real snug),

and assemble.

The hard part is done - and if you've done a reasonably good job of drilling

and gluing, the part is now actually BETTER than new - with the finishing

nail dowel in the pivot pin, the part is protected from risk of future

shearing.

Now for reassembly. If you've got all the parts, this should be accomplished

easily enough. If you're missing the bearing and/or spring, there are some

makeshift replacements:

bearing: copper/brass BB's (not pelets - BBs) may work. Sporting goods store

might have some, or that old Daisy Model 103 sitting in the back of your

closet might have some left in it. Your auto parts store might have some

bearings this size - they might also have a spring too. The bearing is 1/8"

diameter.

Insert the spring into the plastic frame (there is a small recess between the

two contacts), and set the bearing on top of that (note that is is most

easily accomplished with the frame face up).

Take the metal sleeve, if you've completely removed it from the lens, and

jiggle it into place over the pivot hole (on the lens, just under the ground

spring), and use needlenose pliers to get it in (this is fairly easy to do if

you've reshaped it properly). Press it into the pivot hole until it aligns

with the outside of the hole. Drop in the pivot pin, and re-bend the backing

spring (reapplying sufficient pressure on the backside of the pin to push the

tip through the sleeve, being careful about the torque you're placing on the

riveted-through lens).

Holding the frame and lens above your parts tray (in case you should drop the

bearing), insert the lens from the bottom side of the assembly, rebuilt pivot

side first, down onto the bearing. When the side of the sleeve (with tension

on it from the grounding spring) contacts the side of the frame, take your

finger and press it down until it clears (there isn't THAT much spring

pressure on it), and then slide it in. Align the lens such that the sleeve

pops through the pivot hole in the metal frame, and you're home free.

Apply power to the assembly and test. When you're sure it works, remove

power and carefully reapply a flaring to the pivot sleeve, and reinstall

(note, the proper reinstallation would be to insert the hot side first

(since that isn't a spring pivot), and then push the springy side in).

My cabin lights now work like new.

From: Sean.Straw+Jaguar@mail.professional.org

Subject: Toggle lamp/switches - repair procedure

spring: I would have thought that a spring from an "old-style" push-click

cheapo pen would work, but it is too large. Pop it open, steal spring, cut

to fit. This spring looks to be something you'd order from Small Parts, Inc

(1 800 220-4242), and they'd probably have the bearing too. Unfortunatley,

I didn't measure my springs when I had them out, but the spring comes flush

to the top of the hole it rests in, so take a wooden match and sit it in the

hole, mark it and remove it to get the length. 1/4" seems about the size.

Fairly stiff.

If you've got at least one complete lamp, pull it out and take it with you to

the parts counter and see if they can't match the bearing visually - even

when assembled, the bearing is quite visible.![[TOP]](/graphic/JagUpBar.gif)

Sean B. Straw

EMail to: Sean.Straw+Jaguar@mail.professional.org